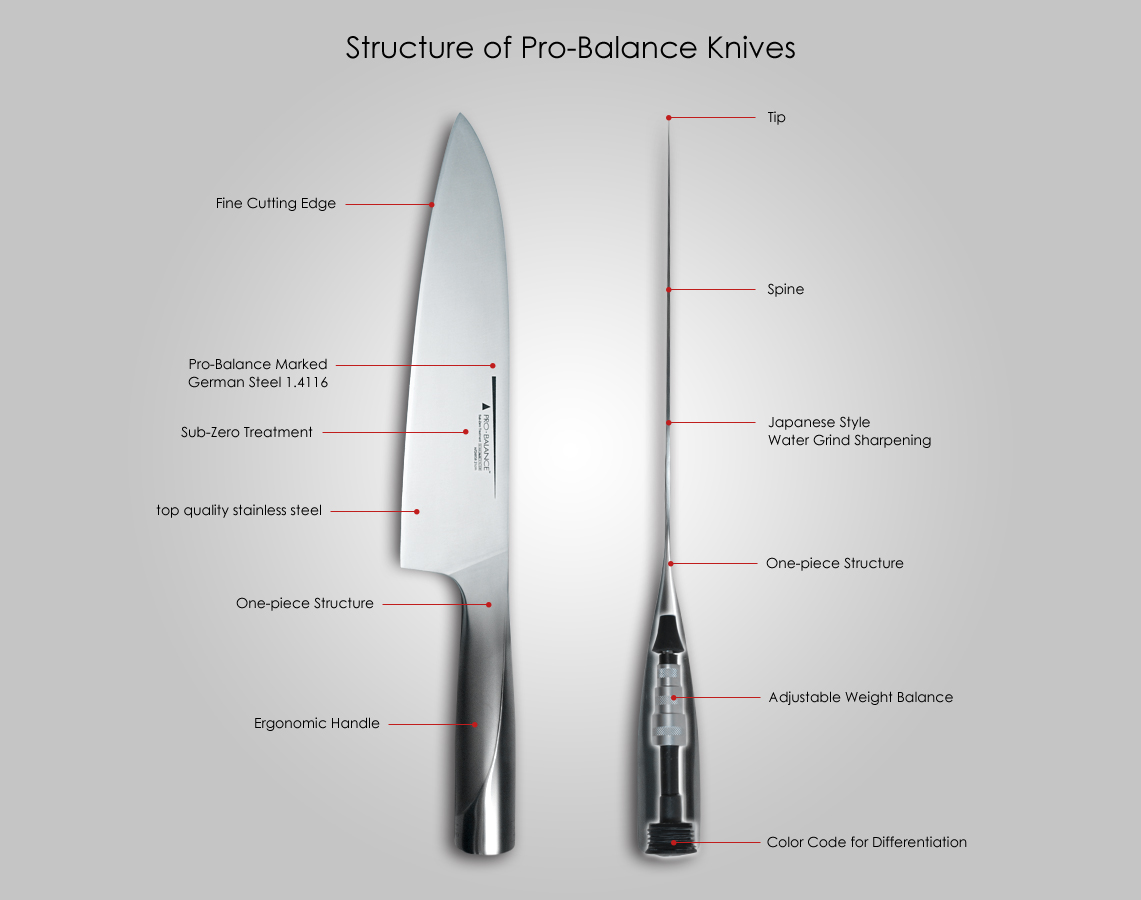

All Pro-Balance knives have been tested for quality assurance to insure the best knives are brought to you.

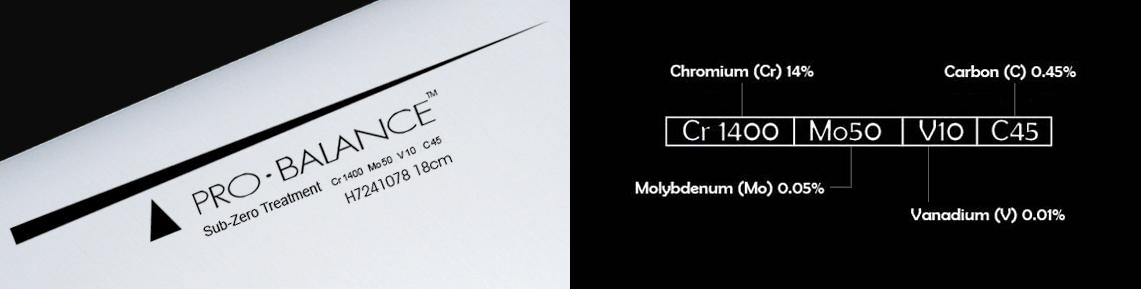

Each knife is marked with a Pro-Balance seal, item number and blade size as well as the processes used to create the knives.

| Chromium (Cr) When Chromium is added to steel, its natural affinity for Oxygen creates a stable Oxide surface film. This protects the surface of the metal from stains, rust and corrosion. When steel is combined with 10.5% Chromium, the resultant alloy is classified as Stainless Steel. Pro-Balance kitchen knives contain more than 14% of Chromium. |

| Molybdenum (Mo) Molybdenum is proven to be useful in applications that involve intense heat, including the manufacturing of aircraft parts, electrical contacts, and industrial motors. Pro-Balance knives contain molybdenum of more than 0.05%, allowing the blade to withstand extreme temperatures without significant physical changes. |

| Vanadium (V) Vanadium forms stable nitrides and carbides. It can significantly increase the strength of the stainless steel. Pro-Balance knives contain up to 0.10% of vanadium, giving the blade the hardness above HRC 55. |

| Carbon (C) Carbon is one of the critical materials in the making of stainless steel. Pro-Balance kitchen knives contain carbon of more than 0.45%. It can significantly enhance the strength and durability of a stainless steel blade. |

| Sub-Zero Treatment The blades are heated up to 1,000°C and then cooled down by using liquid nitrogen which is under -185°C. This hardening process, also known as the Sub-Zero Treatment, can significantly enhance metal cell structures, giving the Pro-Balance knives superior strength, temperature resistance and hardness. |

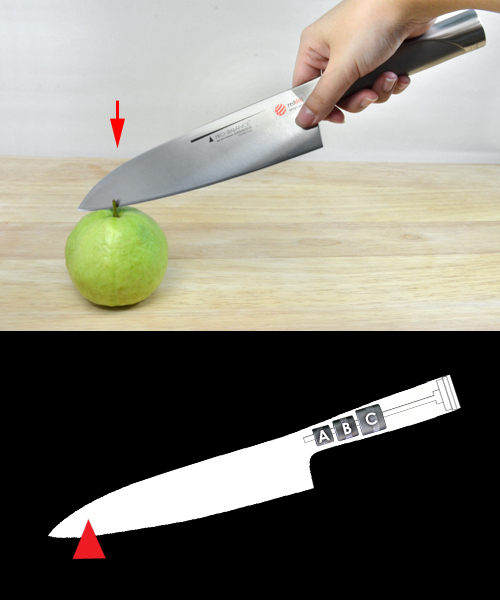

For those who like holding a knife |

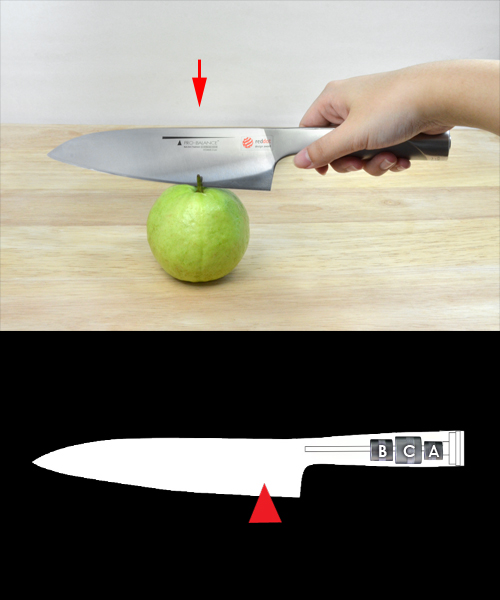

For those who like holding a knife |

|

|

| by placing the weights at the front of the handle, the center of balance will shift toward the front of the blode |

by placing the weights at the end of the handle, the center of balance will shift toward the back of the blade |